Category: Fibre Testing Instruments

Introduction: Experiment 16: Polarized light method for maturity testing of cotton fibersI. Purpose and requirements of the experimentThrough the experiment, understand the structure of polarized light microscope and the principle of Y147 polarized light maturity d…

Through the experiment, understand the structure of polarized light microscope and the principle of Y147 polarized light maturity determination, master the operation of the determination, familiar with the interference color of different maturity of cotton fiber and the determination of cotton fiber maturity.

Test apparatus for polarized light microscope (with polarizer, check polarizer, a level of red or red wafer), Y147 type cotton polarized light maturity meter, hair glass illuminator, the first clip, the limiter black flannel plate, metal comb, slides, glue, scissors, voltage regulator. Specialized Calculating Ruler.

A type of raw cotton.

The polarized light microscope optical system is shown in Figure 16-1.

1. The method of specimen preparation is the same as that for the determination of the maturity of cotton fibers by the mid-cavity cell wall contrast method. In the preparation of the specimen piece of the slide and coverslip between drops of 18% NaOH, so that the fiber expansion, in the polarized light microscope observation will be more clear.

2. Illuminate the microscope glass illumination in the polarized microscope (magnification of 200 or so) on the reflector, and adjust the brightness of the field of view according to the ordinary biological microscope operation.

3. Adjust the polarizer and polarizer polarization surface perpendicular to each other. At this time, the field of view should be completely dark.

4. Place the prepared slide with cotton fiber between the orthogonal polarizer and the polarizer, so that the fiber axis and the polarizing surface of the polarizer intersect at 45 °, and then adjust the focusing device to adjust the position of the mirror, so that the specimen is clear. At this time, the cotton fiber should be bright white, the surrounding field of view is still dark black.

5. Put a level of red or three red wafer compensator. If you use - level red chip, its slow light direction should coincide with the direction of the geometric axis of the cotton fiber. If using three levels of red chip, the direction of the fast light should coincide with the direction of the geometric axis of the cotton fiber. In the first or third level after the red chip, in the polarized light microscope observation, the surrounding field of view is rose red, and cotton fibers due to different maturity, different thickness of the cell wall, it will show a variety of different interference colors.

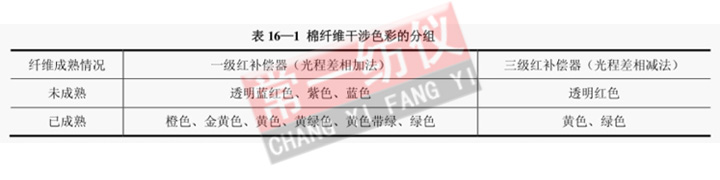

6. In a field of view of the fiber in the middle section of the slide root by root to observe the color in the broad section of the fiber lumen. Determine the maturity of each cotton fiber according to Table 16-1. When the color is difficult to determine, move forward and backward along the fiber axis to observe the decision.

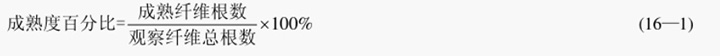

The number of mature and immature fiber roots were recorded separately for calculation. The total number of fibers observed was about 200-300.

1. Turn on the instrument's voltage regulator switch and instrument power switch 1, preheating for about 20min.

2. from the sample sliver, take out the cotton sample, the weight of about 25mg, by hand tugging method to sort out the cotton bunch, so that the fibers are straight and parallel and one end is neat.

3. Use the metal comb to remove the free fiber and shorter than 18mm below the short fiber, and then the cotton bunch into three small cotton bunch. Each small bundle weighs about 5mg.

4. With the left hand to hold a small bundle of cotton neat end, the right hand with the first clip from the tip of a small bundle of cotton layered clamping, one by one on the black velvet board in the limiter, stacked into a neat end, width of about 25mm, and the long fibers under the short fibers in the upper, between the fibers straight, parallel, uniform bundles of cotton.

5. Turn down the restrictor black velvet board - end of the wooden board, and then use - No. clamp from the neat end of the cotton bunch clamping removed, to keep the fibers straight, uniform.

6. Wipe the slide clean and place it on the black velvet plate. Place the straight and even cotton bundle on a position 10mm from one end of the slide, then cover with another slide, clamp it tightly with a small clip, and cut off the fibers exposed on both sides of the slide.

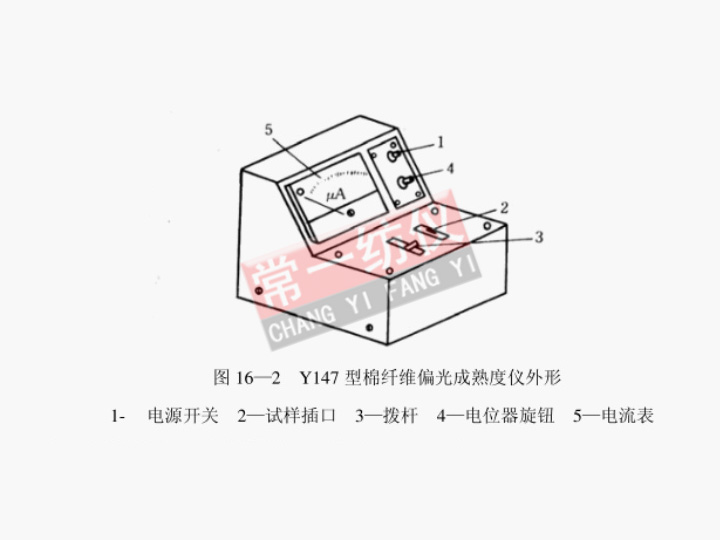

7. Clamp the specimen insert with two blank slides, insert it into the specimen socket 2, and then move the dial lever 3 forward (i.e., the attenuator is pushed into the optical path). Turn the potentiometer knob 4, so that the ammeter 5 pointer on the dial scale "100" (should make the ammeter pointer stabilized in the "100mA" scale, if there are fluctuations should be slightly waiting a few minutes to try again).

8. Withdraw two blank slides of the specimen piece, inserted into the folder with the specimen insert. At this point the ammeter 5 pointer shifted to the left, indicating the number of fibers of the specimen (ammeter 5 pointer in the scale range of 55 ~ 65mA).

9. Move the toggle 3 back (i.e., the polarizer pushed into the optical path). At this time, the ammeter 5 pointer that indicates the specimen in the polarized light intensity readings.

10. According to "8", "9" two steps obtained by the number of fibers and light intensity readings with the instrument accessories in the special ruler, to find the maturity coefficient of the specimen. The special calculation ruler is used as follows:

(1) Calculation ruler in the middle line of the arrow aligned with the lower line of the number of fibers adjusted on the value.

(2) Check off the polarization reading in the middle row.

(3) By the polarized light reading aligned with the upper row of the scale that is the maturity factor.

For example: the number of fibers is 59, the polarized reading is 60, then the maturity coefficient is 1.61.

Previous: YT050 Geotextile Abrasion Tester

Textile instruments are suitable for testing the color fastness of printed and dyed textiles to dry, wet friction, and brushing friction. General textile testing…

The fabric induction static electricity tester is mainly used in the laboratory to identify the static electricity performance of textiles such as fibers, yarns,…

The application of fabric strength machines in industrial production is very extensive, and their automatic control system is an important component of work. In …

1. The operators of textile instruments should use the equipment correctly, strictly follow the operating procedures, prepare carefully before starting, check re…

1. Keep tight. Textile instrument manufacturers introduce that during the use of material testing machines, due to the vibration during testing, it is easy to ca…

Fabric strength machine is a device used for testing the mechanical properties of textiles, such as stretching, tearing, bursting, constant elongation, constant …