Category: Hygiene and protection test equipment

Introduction: Applicable scopeUsed to test the overall protective performance of chemical protective clothing for solid particles;Used to characterize the performance indicators of protective clothing based on the leakage rate of particulate chemical pollution into…

Used to test the overall protective performance of chemical protective clothing for solid particles;

Used to characterize the performance indicators of protective clothing based on the leakage rate of particulate chemical pollution into clothing in the workplace environment;

Used for leakage testing in Chapter 6.4 of GB 2626-2019;

Used for GB 19083-2010 Technical Requirements for Medical Protective Masks Appendix B Sealing;

Generate standard NaC1 particle aerosols through an aerosol generator, pass them into the testing room to maintain a relatively stable state, and the tested object wears the tested protective clothing in the testing room to perform the test action according to a predetermined plan. The particle detector measures the NaC1 particle aerosol concentration inside the tested protective clothing at a fixed sampling point, and evaluates the overall protective performance of the protective clothing against particles based on the following indicators: the single inward leakage rate of each sampling position, Lijmn; The total inward leakage rate Ls of each tested protective suit; The total inward leakage rate LH of each tested object; The total inward leakage rate LE for each test action- The total inward leakage rate LP at each sampling location; The average total inward leakage rate L.

GB/T 29511-2013 Protective Clothing Solid Particle Chemical Protective Clothing 4.3.1 and Appendix A

GB 2626-2019 Respiratory protective equipment - Self suction filter type anti particle respirator - Section 6.4 GB 19083-2010 Technical requirements for medical protective masks - Appendix B - Tightness ISO 13982, BS EN ISO 13982, EN 1073-1-2016 and other standards

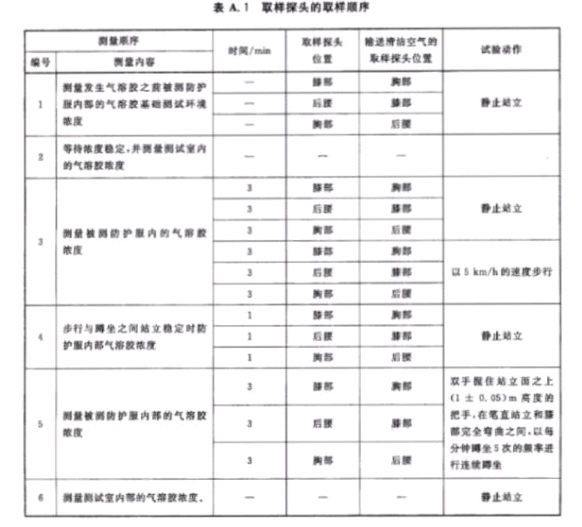

1. Sampling procedure for GB/T 29511-2013 standard:

Table A1 Sampling sequence of sampling probes

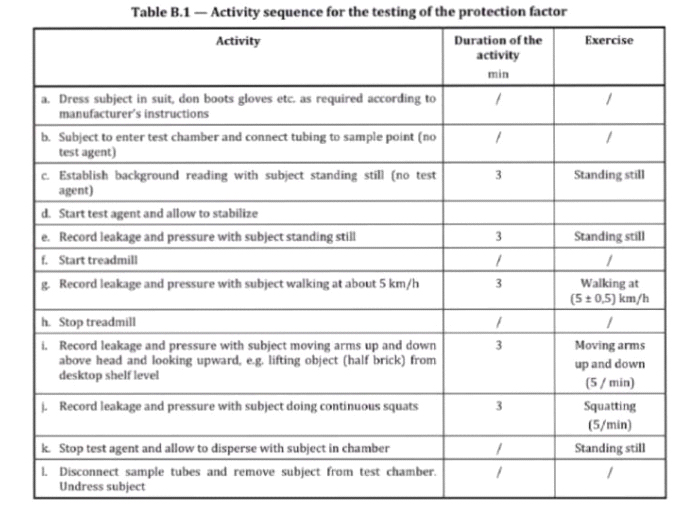

2. Sampling procedure for EN 1073-1-2016 standard:

Table B.1一Activitysequence forthe testingofthe protection factor

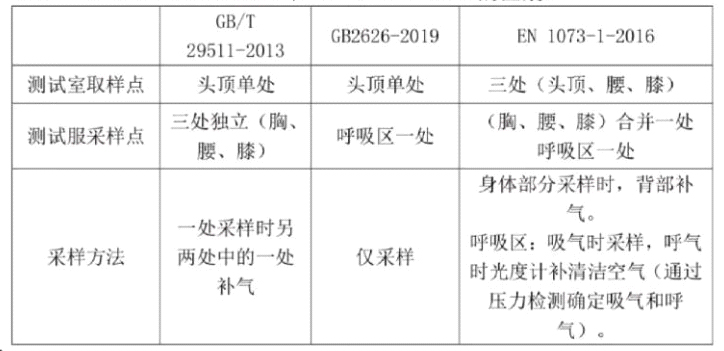

3. Differences between GB/T 29511-2013, GB2626-2019, and EN 1073-1-2016:

1. Environmental temperature (20 ± 5) ℃, relative humidity ≤ 60%

2. ≥ 4000 × 5000 × 3000mm for use in space, with good ventilation for water intake and drainage

1. Walkthrough testing room:

Effective internal dimensions: 1800mm x 1500mm x 2100mm (L x W x H)

Test outdoor dimensions: 1950mm x 1650mm x 2500mm (L x W x H)

Control cabinet size: 700mm x 700mm x 1600mm (L x W x H)

2. Environmental simulation monitoring system

(1) Na Cl particle aerosol generator:

(2) 2 particle concentration detectors

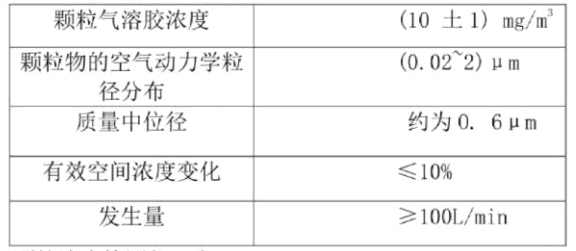

When sampling three parts (head, waist, knee) (chest, waist, knee) combined with one breathing area and one body part in EN 1073-1-2016, replenish air in the back. Breathing area: Sampling during inhalation, supplementing with clean air during exhalation (determined by pressure detection for inhalation and exhalation). (10 soil 1) mg/m (0.02-2) μ M is approximately 0.6 μ The dynamic range of m ≤ 10% ≥ 100L/min is (0.001~200) mg/m3, with an accuracy of ± 1% and a response time of ≤ 500ms. (3) The running speed of the horizontal foot pedal transmission test bench is (5 ± 0.5) km/h. (4) The air duct circulation and maintenance cleaning device

1. Centralized control console, PC programmed control and prompt completion of the entire test process

2. Automatically monitor experimental data, automatically calculate experimental results such as individual internal leakage rate, total internal leakage rate, and average total internal leakage rate, and output experimental results in multiple ways.

1. NaC1 particle aerosol generator

The gas volume shall not be less than 100L/min, and the concentration of NaCl particle aerosols shall be (10 ± 1) mg/m ², The concentration change within the effective space of the testing room is ≤ ± 10%; The aerodynamic particle size distribution of particulate matter should be (0.02-2) μ m. The median diameter of the mass is approximately 0.6 μ M.

2. Particle detector

Two detectors are used to detect the concentration of NaC1 particulate aerosols inside the testing room and the tested protective clothing. The dynamic range is (0.001-200) mg/m ², The accuracy is ± 1%, and the response time of the detector is ≤ 500ms.

3. Horizontal pedal transmission test bench

1 unit, running at a speed of (5 ± 0.5) km/h, installed in the testing room.

4. Sampling pump and air pipeline

Two sets, respectively used for collecting and detecting NaC1 particle aerosols inside the testing room and the tested protective clothing. Flow range (0.05-4) L/min, flow fluctuation<± 0.2L/min. It can be ensured that the sampling probe can sample at a flow rate of (2 ± 0.5) L/min inside the tested protective clothing.

To ensure that the pressure reduction generated by sampling inside the tested protective clothing does not cause additional inward leakage rate, the colleague taking the sample should transport it inside the tested protective clothing at a rate of (2 ± 0.5) L/min. According to the sampling sequence in the schematic diagram, clean air can be input through one of the other two sampling probes in the intermittent sampling state.

5. Sampling probe

Four sampling probes, one of which is used to detect the concentration of NaC1 particle aerosols in the testing room environment, and the other three are used to measure the concentration of NaC1 particle aerosols inside the tested protective clothing. The sampling probe is connected to a transparent plastic tube with an inner diameter of 4.0mm and a suitable length.

Previous: Y175D Micronaire Value Tester

Textile instruments are suitable for testing the color fastness of printed and dyed textiles to dry, wet friction, and brushing friction. General textile testing…

The fabric induction static electricity tester is mainly used in the laboratory to identify the static electricity performance of textiles such as fibers, yarns,…

The application of fabric strength machines in industrial production is very extensive, and their automatic control system is an important component of work. In …

1. The operators of textile instruments should use the equipment correctly, strictly follow the operating procedures, prepare carefully before starting, check re…

1. Keep tight. Textile instrument manufacturers introduce that during the use of material testing machines, due to the vibration during testing, it is easy to ca…

Fabric strength machine is a device used for testing the mechanical properties of textiles, such as stretching, tearing, bursting, constant elongation, constant …